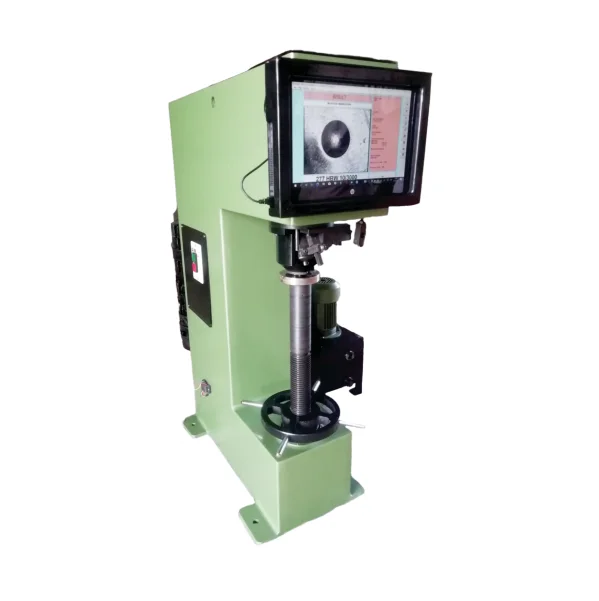

Touch Screen Computerized Brinell Hardness Testing Machine Manufacturers in Maharashtra

Touch Screen Computerized Brinell Hardness Testing Machine

Wide Testing Range from Soft metal to medium hardness Steel. Accuracy Measurement of Brinell Hardness Number using image processing technology Computerized Touch Screen

Technical Specifications

- Computerized Touch Screen Brinell Hardness Testing Machine.

- Accurate Measurement of Brinell Hardness number using “State of the art” image processing technology.

- Wide testing rang : from soft metal up to hardest.

- High accuracy & repeatability of measurement at all loads.

- Faster measurement yielding to higher productivity.

- Small size of indentation makes it a non destructive testing on finished components.

- Hydraulic loading and unloading cycle.

- Advanced windows based software.

- Inbuilt branded touch screen laptop.

- Front panel touch screen display.

Features

- ➞ User-friendly software with windows features.

- ➞ online indentation setting & focusing on the front touch screen display.

- ➞ Advanced image processing: algorithms implemented for precise

- ➞ calculation of hardness numbers with various options to cover all

- ➞ ranges of the specimen.

- ➞ Batch file processing: Option for data storage & reports generation.

- ➞ Statistical Evaluation: Software for calculating standard deviation,

- ➞ mean, median, histogram, etc.

- ➞ Wide options in calibration mode – calibration/verification on PC

- ➞ making it easier to operate.

- ➞ Extensibility for future advanced image processing analysis

- ➞ USB Printer port for printer interface with result & graph print out.

- ➞ Facility to measure in Manual, Semi-automatic & Automatic Mode.

- ➞ Facility to export results/data in PDF format.

Application

touch screen Brinell hardness tester Model B 3000 - TC is a simple and accurate means to produce and automatically measure the indentation to give Brinell hardness number. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range from soft to hard and their accurate results are widely acclaimed. These testers strictly confirms to IS 1500-2.

Application

The machine frame is designed to accommodate the high precision loading system and an optical device with CCD Camera equipped with front touch screen laptop. Specimen is placed on a testing table and brought in contact with clamping cone. Load/Unload/Read operations are done through 3 position hand lever. The image is digitalized using CCD camera fitted on the optical device and is captured by the front touch screen laptop. The diameters of the indentation are directly measured by software to give the Brinell hardness number. The machine is equipped with latest touch screen branded laptop so there is no need to arrange for computer.

Technical Specifcations

- ➞ Test Loads 250 to 3000 in stages of 250kgf.

- ➞ Magnification of objectives 4X

- ➞ Measuring Range 1 to 6mm

- ➞ Maximum Test Height (mm) 380

- ➞ Scale least count (mm) 0.01

- ➞ Throat Depth (mm) 200

- ➞ Machine Dimension (mm) L 1025 x W645 x H1178 Approx.

- ➞ Weight 450 kg. Approx.

- ➞ Power Supply 415V, 50Hz, 3-Ph.

Standard Accessories

- ➞ Testing Table 200mm dia 1 No.

- ➞ Testing Table 70mm dia with ‘V groove for round jobs 10 to 80mm dia. 1 No.

- ➞ Ball Holder 5mm 1 No.

- ➞ Test Block HBW-5/750 1 No.

- ➞ Test Block HBW-10/3000 1 No.

- ➞ Ball Holder 10mm 1 No.

- ➞ Test Block HBW-10/3000 1 No.

- ➞ Allen Spanner 1 Nos.

- ➞ Weights 1 Set

- ➞ USB devise for video 1 No.

- ➞ Instruction Manual 1 Book